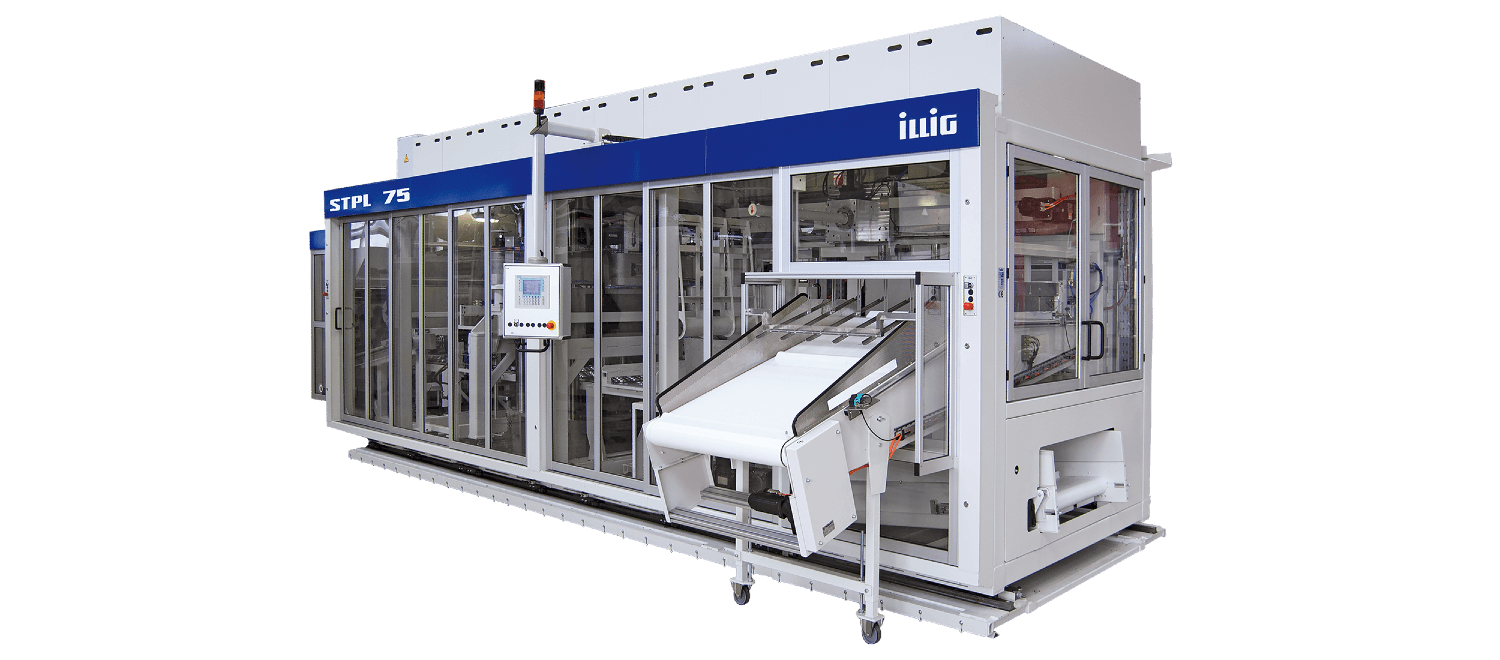

With its STP series stacking systems for formed and punched parts, ILLIG offers a variety of different stacking systems depending on the technical properties of the thermoforming machine in the production line. The stacking systems are designed to accommodate the degree of automation, output performance and productivity of the thermoforming machine, as well as the required post-processing. Because the forming part properties also depend on the quality and reliability of the downstream machines in the production line. The formed parts are either moved directly into a stacking magazine with an ejector in the tool, or picked up and held in place by a vacuum system during the transfer phase and then stacked. This avoids deforming the formed part and improves part cooling. It is possible to install customer-specific equipment.

STPL 75b

With its STP series stacking systems for formed and punched parts, ILLIG offers a variety of different stacking systems depending on the technical properties of the thermoforming machine in the production line.

Overview

STPL 75b

Specifications

Forming Area

856 mm X 530 mm

Cycle Speed

Formed Part Height

min. 25 mm max. 210 mm

Have a Question about STPL 75b? Just get in touch