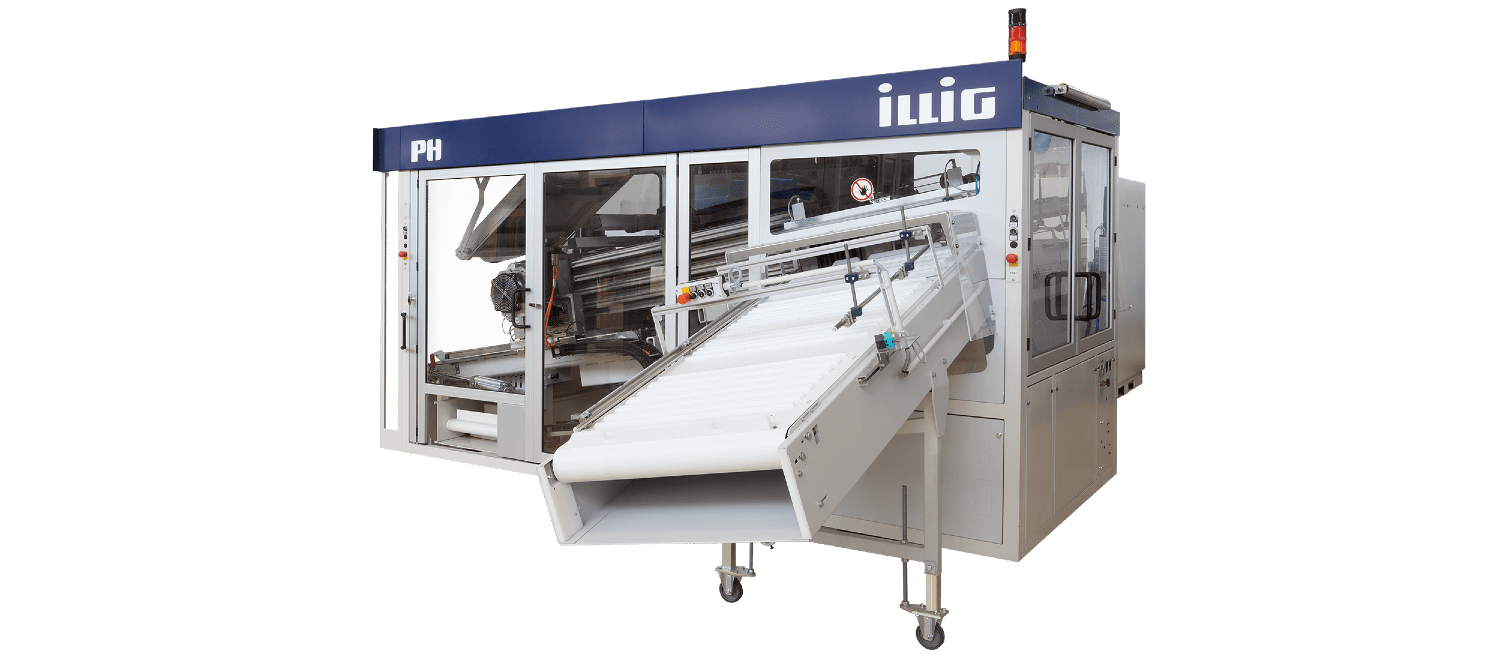

With its PH series product handling systems, ILLIG offers a variety of different stacking systems depending on the technical properties of the thermoforming machine in the production line. Because the product properties also depend on the quality and reliability of the downstream machines in the production line.

The different stacking stations range from a simple manual part removal to a fully automated stacking system with feed units to downstream machines, such as a cup rim rolling machine, bag or sleeve packer, and more. The formed parts are either moved directly into a stacking magazine with an ejector in the tool, or picked up and held in place by a vacuum system during the transfer phase and then stacked. This avoids deforming the formed part and improves part cooling.