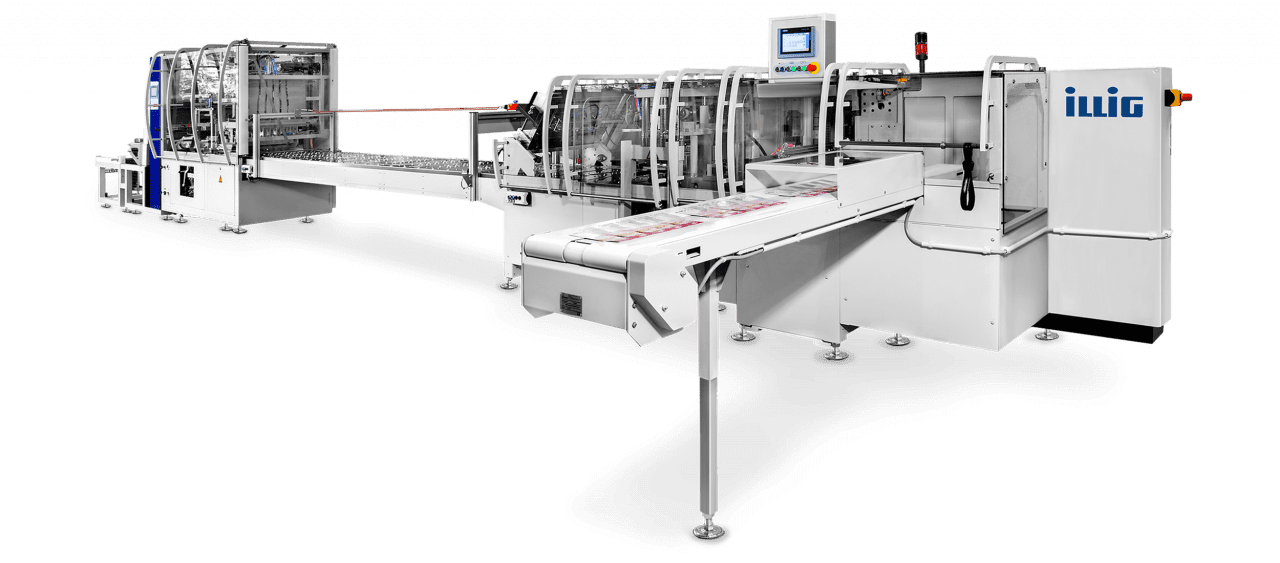

The ILLIG HSA 50d automatic heat sealing machine is a production system with a maximum forming area of 500 x 300 mm that is highly adaptable to your individual requirements. Insert card feeders and pack lift-out devices can be positioned freely between the thermoforming unit and the sealing station. The thermoforming unit provides greater feed-length accuracy through its servo-driven material transport, which also improves the cutting accuracy of the blisters. An optimized blister transfer enables smooth and jerk-free motion sequences for loading the blisters into the sealing pallets. The modularly built machine makes it possible to produce a variety of different packaging designs. Exchanging modules and adding new ones is quick and easy. You can extend the production line after the sealing station by integrating labeling or coders, for example, with minimal effort.