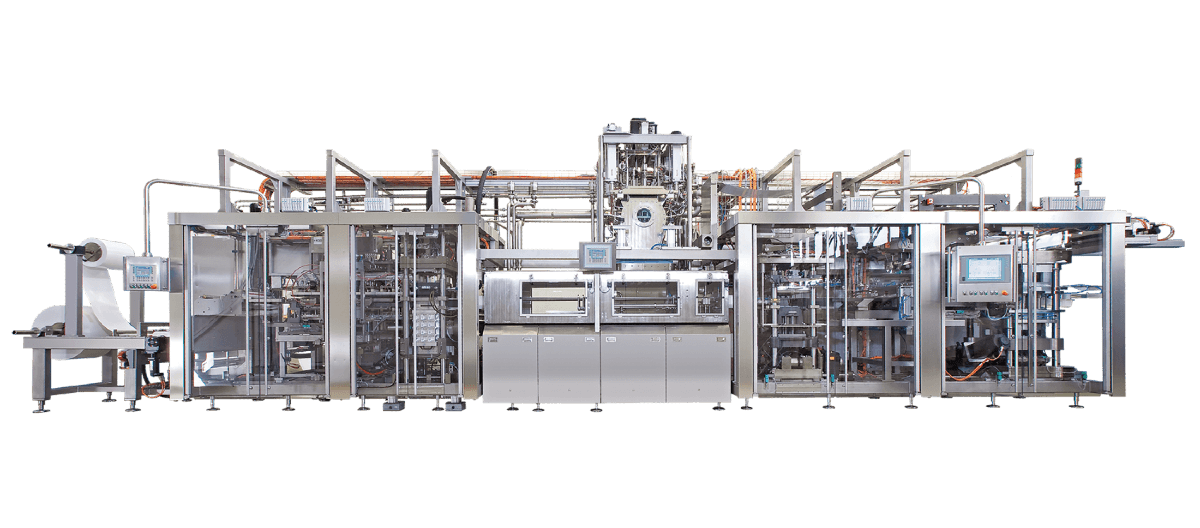

The FSL 48 form, fill and seal machine has a modular design and offers a variety of different options to meet your individual requirements. The economic FFS line, in all stainless-steel version for CIP and SIP, has a maximum forming area of 480 x 330 mm. A format layout between 10 and 24 packs per cycle enables the production of 10,000 to 40,000 packs per hour. The integrated in-mold labeling station (IML-T®) enables brilliant decoration on 1, 2, 3, 4, or all 5 sides of the pack. This guarantees premium-quality marketing for your product. The machine line can fill up to 8 different flavors and decorate them accordingly, at the same time. In contrast to wrap labeling, right-angle walls are not necessary. The discharge system is prepared for every type of packaging: round, oval, rectangular, or asymmetrical. The size of the forming area has been dimensioned so that a complete machine cycle can always be directly deposited onto a EUR-pallet in the box. The hygiene levels Clean, Ultra-Clean and Aseptic are available depending on the requirements.

FSL 48

The FSL 48 form, fill and seal machine has a modular design and offers a variety of different options to meet your individual requirements.

Overview

FSL 48

Specifications

Forming Area

480 mm X 330 mm

Cycle Speed

max. 30 cpm

Formed Part Height

max. 100 mm

Have a Question about FSL 48? Just get in touch