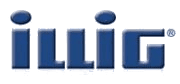

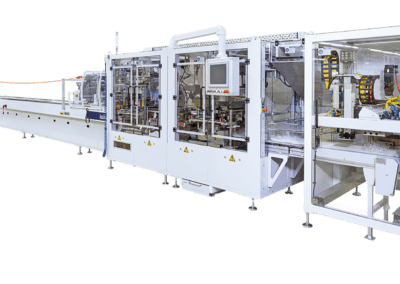

The ILLIG machine range gives a variety of options in manufacturing blisters, from the HSA series automatic heat sealing machines consisting of a thermoforming unit and a sealing unit, to the modular built hot seal unit HSU35b with flexible pallet transport system.

An insert card feeder and pack lift-out device augment the production line for manufacturing modern blister packs with transparent thermoformed blisters. ILLIG developed the BSA 37 automatic blister sealing machine exclusively for non-food packaging. It provides high production reliability and the possibility to manufacture a variety of different packaging solutions with flexible modular equipment, and requires only a short retooling and setup time. The modularly built Hot Seal Unit 35b series with a flexible pallet transport system can be easily adapted to accommodate individual requirements and brings proven technology in an all new concept for the new Design4Recycling (D4R) standard. The efficient and cost-effective machines are ideal for all types of blisters – even 100% cardboard or plastic-cardboard combinations – in the non-food and pharmaceutical industries.