The ILLIG RV 53 automatic vacuum forming machine is designed for cost-effective production of small to medium-sized batches with low tool costs. With a maximum forming area of 500 mm x 350 mm and up to three bar pressure forming air

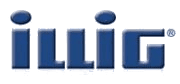

SZA 73d

The ILLIG SZA 73d stacking station, specially designed for the automatic roll-fed forming machine of the RDM series, is equipped with a mechanical and electrical interface for interoperation with the connected RDM forming machine.

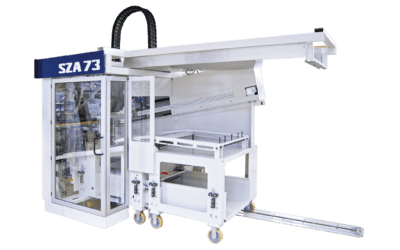

PHF 80

The new PHF 80 product handling system utilizes the full cycle speed potential of the thermoforming machine, increasing the productivity of the line.

PH

With its PH series product handling systems, ILLIG offers a variety of different stacking systems depending on the technical properties of the thermoforming machine in the production line.

STPL 75b

With its STP series stacking systems for formed and punched parts, ILLIG offers a variety of different stacking systems depending on the technical properties of the thermoforming machine in the production line.

RDML 70b

ILLIG holds the patent to the in-mold labeling technology in thermoforming (IML-T®) one of many ILLIG milestones in the thermoforming industry.

RDM 76K

The automatic pressure-forming machine RDM 76K 4G with a forming area of 760 mm x 540 mm is a thermoformer of the 4th generation.

RDM 37/10

The ILLIG RDM 37/10 automatic pressure forming machine with a forming area of 475 mm x 250 mm

RDM 54K

The automatic pressure-forming machine RDM 54K with a forming area of 500 mm x 300 mm processes material film from the roll or inline directly from a connected extruder using combined in-place forming and pass-through punching tools.

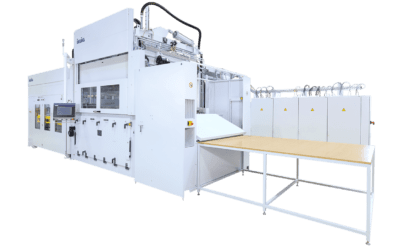

UA 225g

The UA 225g sheet-processing machine has a maximum forming area of 2,200 mm x 1,200 mm.