Working closely with the client and our German manufacturing centre, Illig UK significantly improved the manufacturing schedule during October and November 2020. These improvements meant the machine was installed before the Christmas break and the customer could commence production earlier.

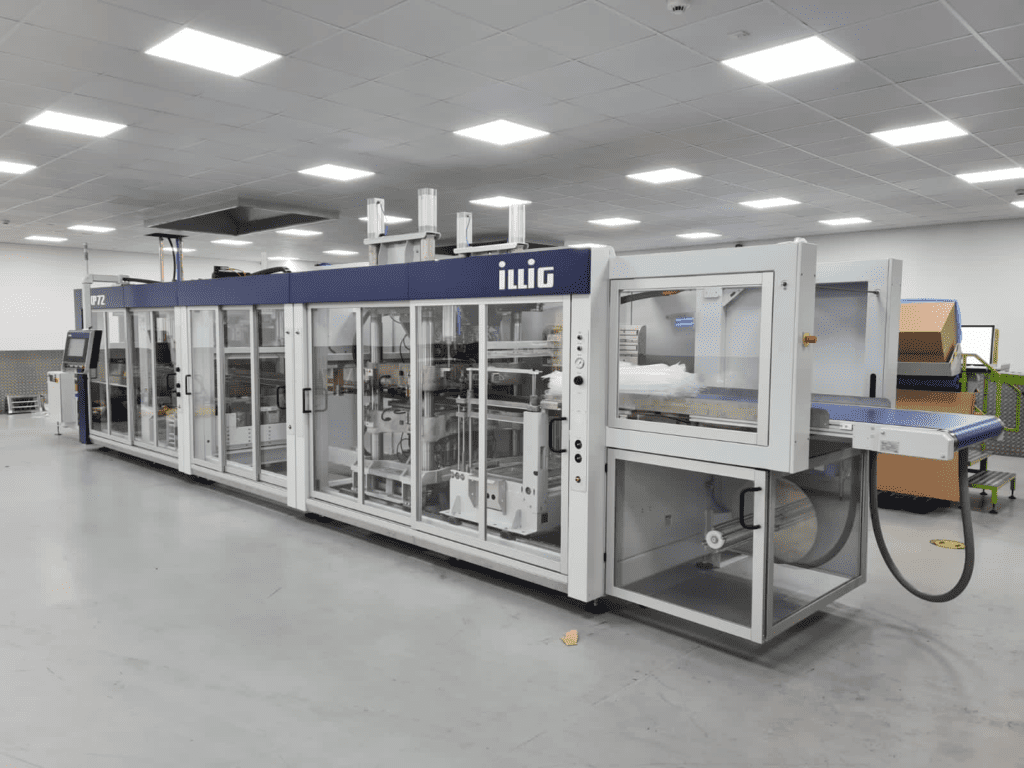

RDKP 72k- an automatic pressure forming machine

This installation was our latest version of RDKP 72k– an automatic pressure forming machine capable of running in production at 55 cycles per minute. Incorporating Illig’s latest developments – IC process control, servo driven clamping frames, punch press with 600kN closing force, servo-controlled stacking station (with ability for alternative stacking arrangements).

The line included a bridging section (empty frame) as per client specifications to retrofit 3rd party equipment for robotic assisted item placement directly into the machine- a further benefit of Illig’s modular production line technology.

Illig UK service team Rob Grummett and Jim Hill arrived at client manufacturing site in the UK, overseeing every stage- beginning with taking delivery of the machine from Germany. Catching up after the completed commissioning, Rob confirmed the installation went to plan and Illig UK received good feedback from the customer. Jim added that all work was completed well within the standard timeframe for such a specified RDKP 72k, a great team effort.

As part of the commissioning arrangement, Rob will keep in contact with the client and revisit their site early in the new year.

Illig UK amended protocols at the start of the UK Covid restrictions to ensure all these essential works were inline with government guidelines- ensuring we could service and support our client base in the food packaging industry keeping up with the ever-present demands from the large supermarket chains.

Our client was keen to add;

We recently accepted delivery of another RDKP 72k and as per the usual standards the Illig engineers were both professional and efficient. The machine was ready to use within 72 hours.