‘Engineering excellence’– the general term used by the industry to describe Illig’s RDM machinery. When looking to produce highly accurate large volumes of thermoformed products, our RDM punch and die tilt bed machinery is the industry standard, the ‘go to’.

Now through years of research, we have developed the downstream integrated RDML decorating system. Yet another significant reason for the industry to stand up and take note.

The RDML decorating unit combines the benefits of highly accurate thermoformed products from the RDM line, with the addition of high-quality decoration opportunities. Bringing light weight products, accurate material distribution, repeatability and flexibility with labelling, all within a single process.

Why choose TIML.

Going forward plastic packaging needs to deliver the normal packaging requirements, (protection, containment, shelf presence, ease of use, etc.) plus include / incorporate the present climate and environment aspects. i.e. lightest packaging weights possible, using widely recyclable materials (containing a certain content of recycled material) & yet fully recyclable in its own right (circular economy).

So, with the change to push plastic products and packaging to be as efficient as possible, Illig focused developments to meet the above criteria.

Looking at one of these developments, we take the case for Plastic and Cardboard combination packaging. With the TIML system, Illig have already confirmed this system runs PP with PP labels or PS and Paper labels. Now the growth of rPET becomes a focus to ensure recycled materials can also be decorated with Paper or Card & potentially PET labels as well.

Looking at rPET and paper label the benefits are clear – with high levels of recycled content in the plastic (up to 100% recycled content possible) a paper label (washes off in water > 60°C.) provides the market with a highly recyclable decorated item. In addition, it is cost-effective, with high output efficiencies and lower manning / production times, a real win/win situation.

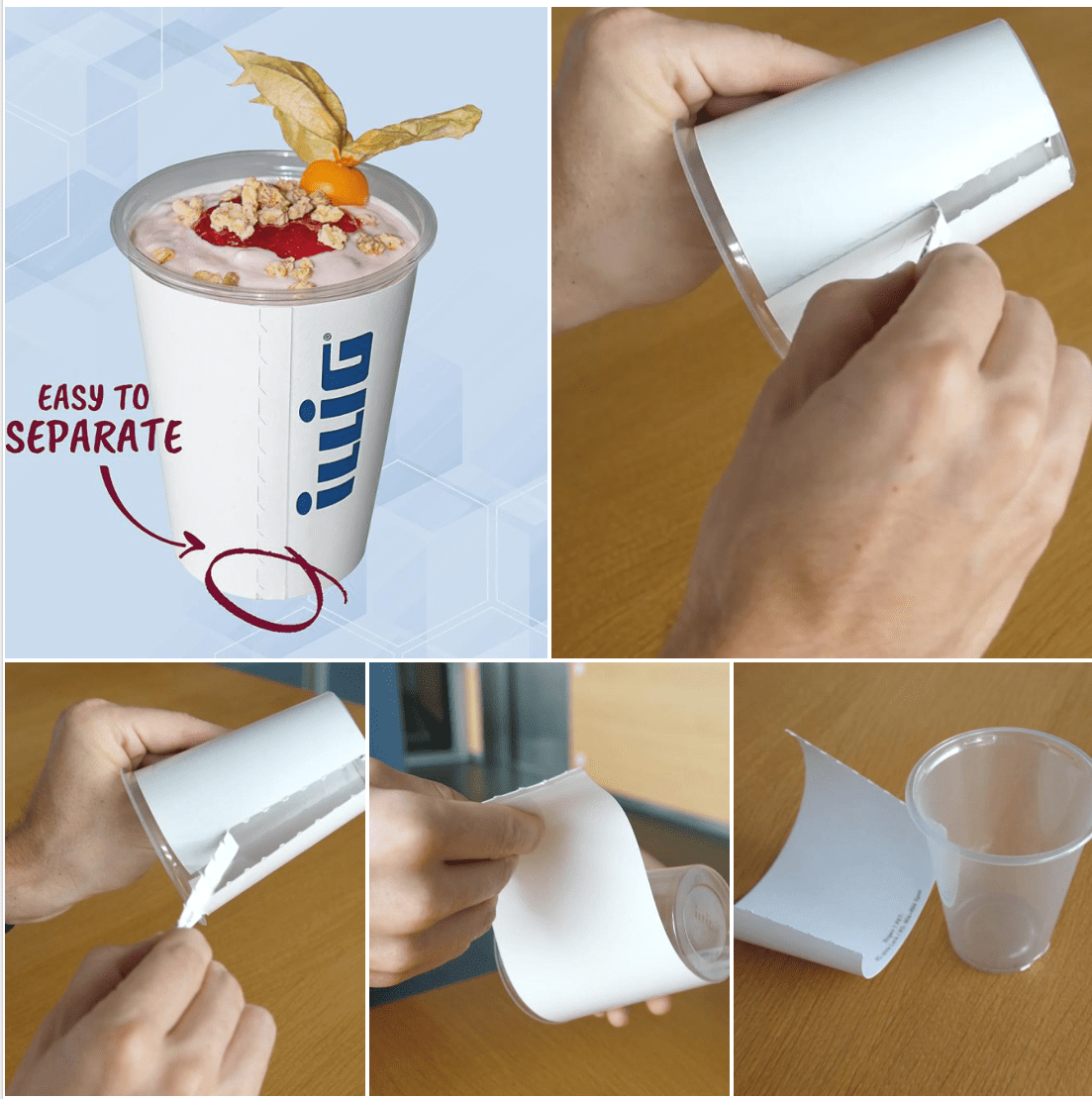

However, Illig did not stop there, with a continued development focused on card decoration, we can now present TIML with rPET (up to 100% recycled content) and card label. The additional benefits became obvious – with unprecedented reductions in plastic content (Up to 40% seen). The cardboard label framework supplied the top load strength, in addition this development can include a design feature to produce packaging with or without adhesive contact between substrates.

TIML from Illig- single stage decoration reducing production costs, best flexibility, and lightest packaging options. Don’t believe me? Put us to the test.

Present us with your problem and enquire directly